Whatsapp:+86-15093113821

Whatsapp:+86-15093113821

Vibrating feeder is used to feed rocks to primary crushing equipment continuously and evenly in the sand and gravel production line to avoid blockage of the crusher receiving port. In the production process, it can feed the lumpy and granular materials from the storage bin to the receiving device continuously, evenly and regularly, thus preventing the receiving device from dying due to uneven feeding and prolonging the service life of the equipment.

Applied material:Limestone, granite, basalt, andesite, granite, quartz, pebble, copper ore, iron ore, gold ore, concrete etc.

Processing ability:50-1200 t/h

Products on this list are top trending product model

We are committed to improve technology, design, process and professional service.

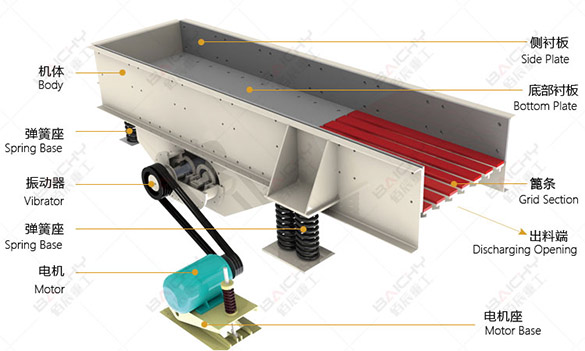

Vibrating feeder is made of vibrating frame, spring, vibrator, motor vibrating device and motor. The vibrator consists two fixed eccentric shafts whose gears are jogged. When installation, the two gears must be jogged according to the sign. By drive of the motor, the two eccentric shafts start rotating to generate a linear huge power which forces the feeder to vibrate back and forth. Through the vibration, The materials will slip and sling on the funnel, moving forward, when the materials pass the screening part, smaller material will fall down, avoiding the further crushing, so screening purpose is reached.

| Model | Chute Size(mm) |

Max feed size(mm) |

Capacity (t/h) |

Motor power(kw) |

|---|---|---|---|---|

| ZSW-650*2500 | 650*2500 | 300 | 50-80 | 5.5 |

| ZSW-850*3000 | 850*3000 | 400 | 80-120 | 7.5 |

| ZSW-960*3800 | 950*3800 | 500 | 120-210 | 11 |

| ZSW-1100*4200 | 1100*4200 | 580 | 200-430 | 15 |

| ZSW-1100*4900 | 1100*4900 | 580 | 280-500 | 15 |

| ZSW-1300*4900 | 1300*4900 | 650 | 450-600 | 22 |

*Capacity is related to material hardness and size.

If you would like to get more product details and quotations, please contact us !