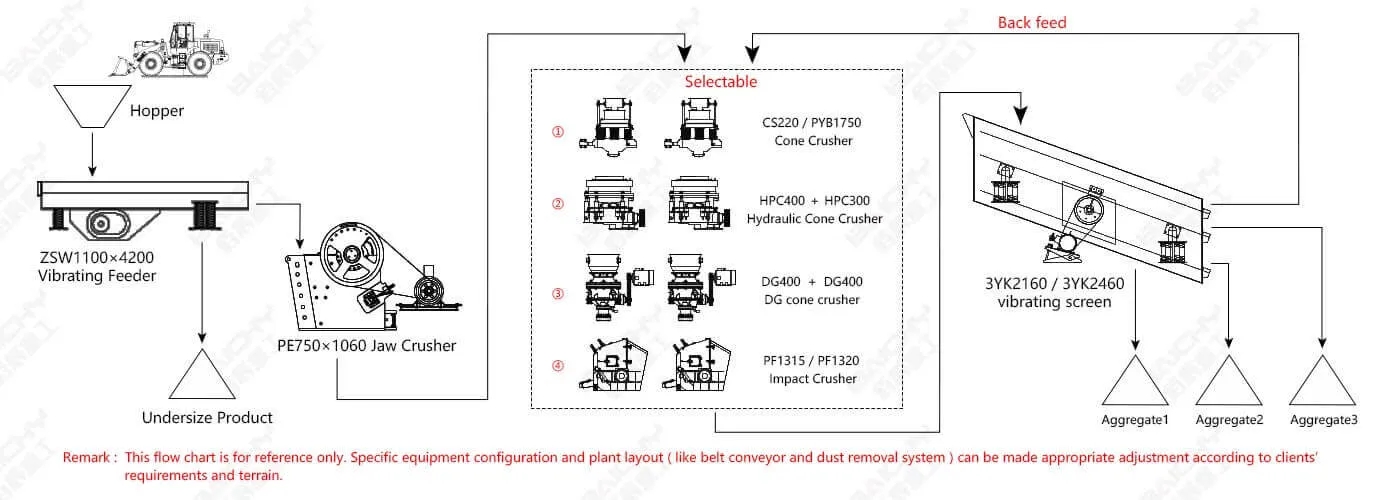

1. The truck transfer the original stone with input size under 700mm into vibrating feeder then to jaw crusher. 2. After first crushing to get 100mm size, it goes to second cone crusher for fine crushing. 3.The output (0-50mm) of cone crusher transfer to the first vibrating screen by belt conveyor to screen. 4. The size over 50mm go back to cone crusher, and the size under 25mm go to another vibrating screen to get size 0-6mm,6-12mm,12-19mm,19-25mm.

As a professional stone crusher plant equipment manufacturer, Baichy Machinery insists on providing customers with high yield, energy-saving and environmental protection rock crushers and other machines. We can customize stone crusher plants for customers, including stone crusher plant layout, stone crusher plant machines and stone crusher plant estimated cost.

If you would like to get more product details and quotations, please con- tact us !