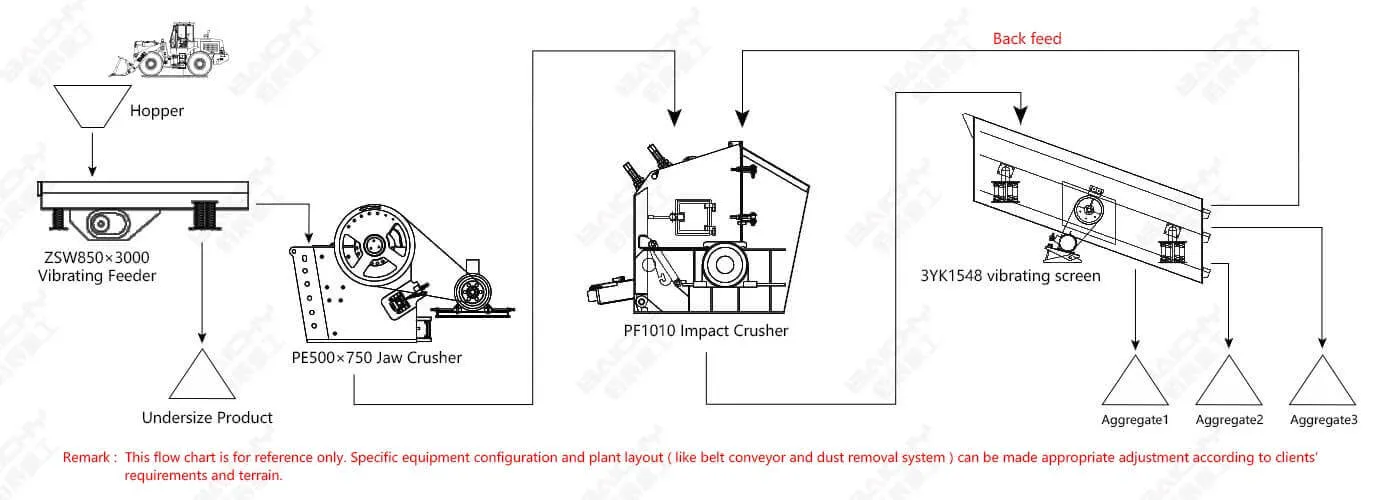

Stone crusher plant is mainly for large lump stones crushing and breaking into smaller size and produce aggregates, gravels and sand. The final size is 0-6mm, 6-12mm, 12-25mm as aggregate for construction.

The truck unloads the stones into the hopper, the stone enters the vibrating feeder from the lower part of the hopper. The vibrating feeder feeds the stones evenly to the primary jaw crusher. The crushed output materials from the primary jaw crusher will be transported to the secondary cone crusher. The crushed output materials from the secondary crusher will be transported to vibrating screen to get final aggregates.

If you would like to get more product details and quotations, please con- tact us !