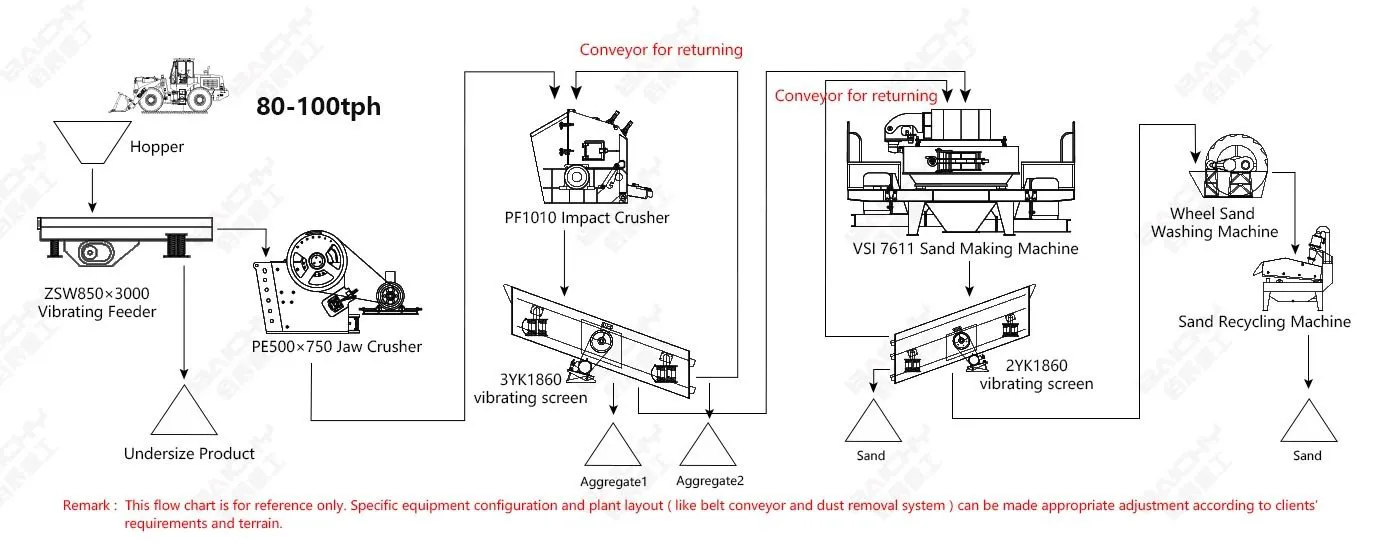

1. Crush and screen process Raw stone materials go to Jaw crusher for primary crushing. Then the materials are transferred by the belt conveyor to secondary crusher ( impact crusher or Cone crusher) for further crushing. Vibrating screen will grade the materials, where stones that meet the granularity standard will be sent to VSI crusher (sand-maker), while the rest will be returned to crush again. Materials that don’t meet the required particle size will be sent back to the sand maker for further process or as final aggregate products. In wet type, the screen could be add a water-spraying system to remove the impurities in advance.

2. Sand washing process Part of the stones processed by VSI crusher (sand maker) will be made into sand and become sand products after being washed by sand washing machine and sand recycling machine. The sand washing machine could choose wheel type or spiral ty pe based on the site situation. Sand dewartering and recylcing machine is to help get fine sand and prevent sand loss. Filter machine and sand dryer is optional too according to demand. After the washing process, we get the finished products.

If you would like to get more product details and quotations, please con- tact us !