Whatsapp:+86-15093113821

Whatsapp:+86-15093113821

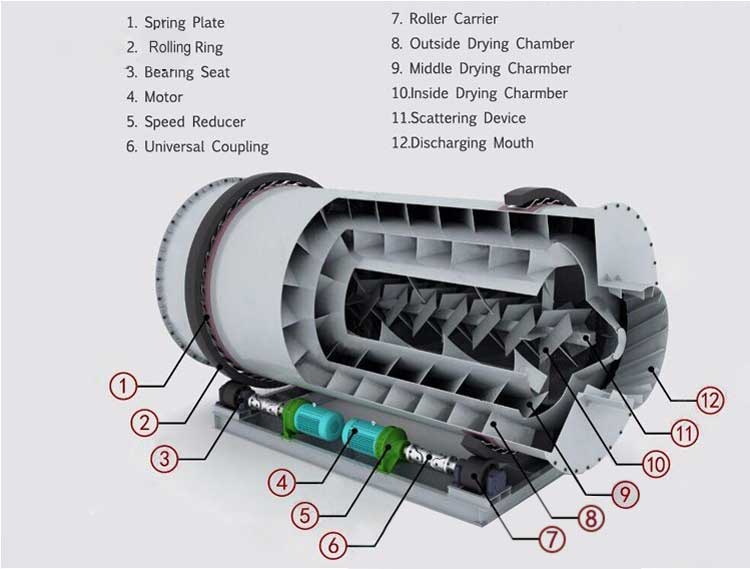

The three-cylinder rotary dryer is to shorten overall size of the dryer body by changing the single drum dryer into three nested cylinders. The cylinder part of the dryer is composed of three coaxial and horizontal inner, middle and outer cylinders stacked, which makes full use of the cross section of the cylinder. It greatly reduces the floor area and plant construction area.

Application: The three-cylinder dryer is widely used in drying sand, slag, clay, coal, iron powder, mineral powder and other mixed materials in various industries, dry-mixed mortar in the construction industry, river sand, yellow sand, etc

Processing ability:8-100 t/h

Products on this list are top trending product model

We are committed to improve technology, design, process and professional service.

Raw material enters the inner layer of the rotary dryer from the feeding device to downstream drying. After, scattered and dried in a sprial way, it enters the middle layer for drying. Heat from inner and middle drum dries material efficiently and the drying time is prolonged. Material travels in a rectangular multi-loop way in the outer drum to finish drying process.

| Model | Rotate speed(r/min) |

Input Temp(℃) |

Power (kw) |

Capacity (t/h) |

|---|---|---|---|---|

| Ф2.0x4m | 4-10 | ≤700-750 | 5.5x2 | 8-15 |

| Ф2.2x5m | 4-10 | ≤700-750 | 5.5x2 | 12-20 |

| Ф2.5x6m | 4-10 | ≤700-750 | 7.5x2 | 18-28 |

| Ф2.8x6m | 4-10 | ≤700-750 | 11x2 | 25-35 |

| Ф3.0x6m | 4-10 | ≤700-750 | 7.5x4 | 30-40 |

| Ф3.0x7m | 4-10 | ≤700-750 | 7.5x4 | 30-45 |

| Ф3.2x7m | 4-10 | ≤700-750 | 11x4 | 35-55 |

| Ф3.6x8m | 4-10 | ≤700-750 | 18.5x4 | 55-75 |

| Ф4.0x10m | 4-10 | ≤700-750 | 22x4 | 70-100 |

*Capacity is related to material hardness and size.

If you would like to get more product details and quotations, please contact us !