Whatsapp:+86-15093113821

Whatsapp:+86-15093113821

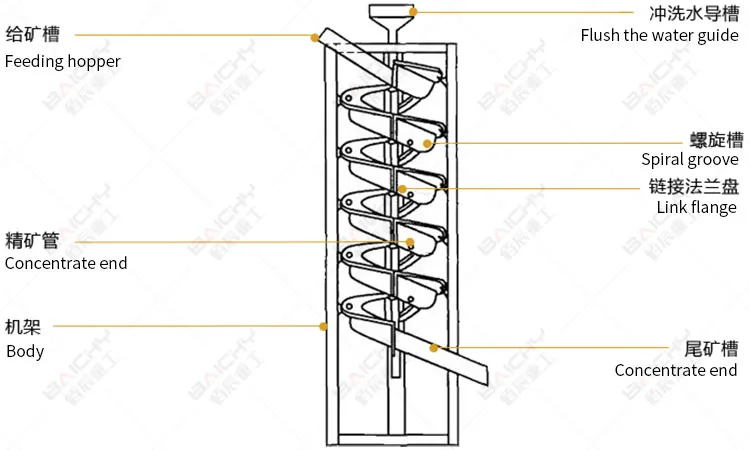

The spiral chute is a gravity separation device that uses the inertial centrifugal force generated by the pulp during the spiral rotary motion to separate light and heavy minerals.

Applied material: It is mainly used for sorting fine-grained iron ore, ilmenite, chromite, pyrite, zircon, rutile, monazite, phosphorite, tungsten ore, tin ore, tantalum ore etc.

Processing ability:0.2-8 t/h

Products on this list are top trending product model

We are committed to improve technology, design, process and professional service.

Ore pulps are uniformly fed into machine and form different layers as they pass across chute. Heavy minerals precipitate to bottom and are moved toward inner edge by the comprehensive action of various forces; light minerals are moved toward outer inner due to the speedy rotation. As a result, mineral particles with different density are divided into three zones-concentrate, middling and tailing.

| Model | 5LL-1500 | 5LL-1200 | 5LL-900 | 5LL-600 | 5LL-400 |

| Outside Diameter (mm) | 1500 | 1200 | 900 | 600 | 400 |

| Screw Pitch (mm) | 900, 675 | 900, 720, 540 | 675, 540, 405 | 450, 360, 270 | 240, 180 |

| Pitch Diameter Ratio | 0.48, 0.36 | 0.75, 0.6, 0.45 | 0.75, 0.6, 0.45 | 0.75, 0.6, 0.45 | 0.6, 0.45 |

| Lateral slope(degree) | 9° | 9° | 9° | 9° | 9° |

| Max. Screw Numbers | 4 | 4 | 4 | 2 | 2 |

| Feed Size(mm) | 0.8 ~ 0.037 | 0.3 ~ 0.03 | 0.3 ~ 0.03 | 0.2 ~ 0.02 | 0.2 ~ 0.02 |

| Feed Density (%) | 30 ~ 55 | 25 ~ 55 | 25 ~ 55 | 25 ~ 55 | 25 ~ 55 |

| Capacity (t/h) | 6 ~ 8 | 4 ~ 6 | 2 ~ 3 | 0.8 ~ 1.2 | 0.15 ~ 0.2 |

| Length (mm) | 1600 | 1360 | 1060 | 700 | 460 |

| Width (mm) | 1600 | 1360 | 1060 | 700 | 460 |

| Height (mm) | 5300 | 5230 | 4000 | 2600 | 1500 |

| Weight (kg) | 850/800 | 700/650/600 | 450/400/350 | 150/120/100 | 50 |

*Capacity is related to material hardness and size.

If you would like to get more product details and quotations, please contact us !