Whatsapp:+86-15093113821

Whatsapp:+86-15093113821

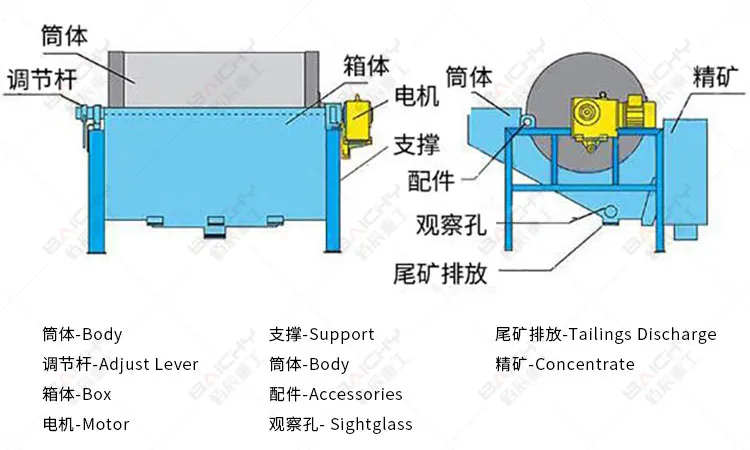

Permanent drum magnetic separator is a magnetic separation equipment for various metallurgical mines to separate magnetic fine particles or remove magnetic minerals mixed in non-magnetic minerals. Wet magnetic separator is a commonly used magnetic separation equipment in iron ore processing plants, which requires water as a medium to sort fine particles of ore.

Applied material:Magnetic separator is mainly used for magnetite, limonite, ilmenite, etc. It can separate elemental minerals from gangue, sediment to improve the quality of minerals.

Processing ability:8-200 t/h

Products on this list are top trending product model

We are committed to improve technology, design, process and professional service.

Slurry enters chute through ore tank, and then gets into separating zone by waterpower. Minerals with strong magnetism is absorbed on the barrel’s surface and get into the ore concentrate outlet, Gangue and ore with weak magnetism are discharged into a pipe in the opposite direction of cylinder rotation.

| Model | Magnetic field intensity (oe) |

Capacity (t/h) |

Power (kw) |

|---|---|---|---|

| CTB600X900 | 1450 | 8-15 | 1.1 |

| CTB600X1800 | 1500 | 15-25 | 2.2 |

| CTB750X1800 | 1550 | 30-45 | 3 |

| CTB900X1800 | 1650 | 35-60 | 4 |

| CTB1050X2400 | 1650 | 60-95 | 5.5 |

| CTB1200X3000 | 1650 | 80-150 | 7.5 |

| CTB1500X3000 | 1650 | 120-200 | 11 |

*Capacity is related to material hardness and size.

If you would like to get more product details and quotations, please contact us !