Whatsapp:+86-15093113821

Whatsapp:+86-15093113821

Rotary kiln is a high-temperature treatment facility used to heat the material to high temperature through calcining in a continuous process. They can also be used in the front stages of metal extraction by roasting sulfide ores in various ways to prepare ores for smelting.

Applied material:Limestone, granite, basalt, andesite, granite in cement,metallurgical industry.

Processing ability:300-1800 t/d

Products on this list are top trending product model

We are committed to improve technology, design, process and professional service.

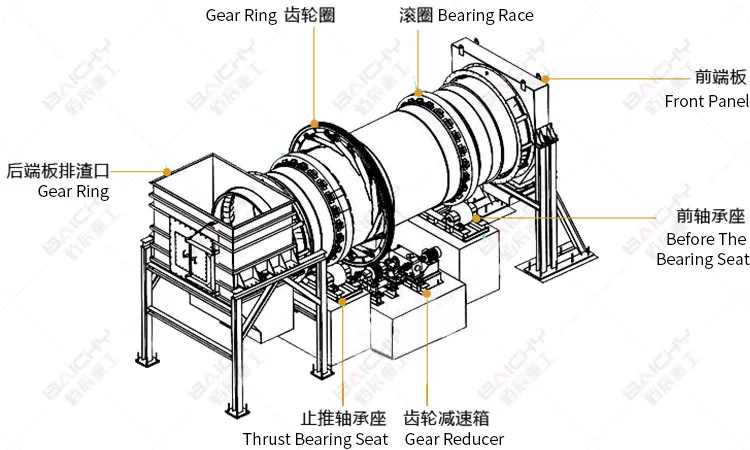

The material will be calcined in the shell after feeding at the head of the kiln. The fuel will be spurted from the kiln tail and start burning. The hot air from the end blow into the kiln directly impacting the raw materials. And then will be turned over along the direction of circle and mixing from the high-end to low-end along the axial because of the shell’s slope and low speed rotation. The material will be calcined into the clinker after discomposition, calcination and cooling process. So they will discharge from the low-end.

| Model | Capacity (t/h) |

Incl omatopm (%) |

Brace (pc) |

Gear Wheel |

|---|---|---|---|---|

| Ф2.8/2.4*44 | 300 | 3.5 | 3 | machine |

| Ф3.2*52 | 600 | 3.5 | 3 | machine |

| Ф3*48 | 700 | 3.5 | 3 | machine |

| Ф3.2*50 | 1000 | 3.5 | 3 | hydraumatic |

| Ф3.2*50 | 1200 | 4 | 3 | hydraumatic |

| Ф3.3*50 | 1200 | 4 | 3 | hydraumatic |

| Ф3.5*54 | 1500-1800 | 4 | 3 | hydraumatic |

| Ф4*60 | 2500 | 4 | 3 | hydraumatic |

| Ф4.6*64 | 3500 | 4 | 3 | hydraumatic |

| Ф4.8*74 | 5000 | 4 | 3 | hydraumatic |

| Ф5*74 | 6000 | 4 | 3 | hydraumatic |

| Ф5.6*87 | 8000 | 4 | 3 | hydraumatic |

| Ф6*95 | 10000 | 4 | 3 | hydraumatic |

*Capacity is related to material hardness and size.

If you would like to get more product details and quotations, please contact us !