Whatsapp:+86-15093113821

Whatsapp:+86-15093113821

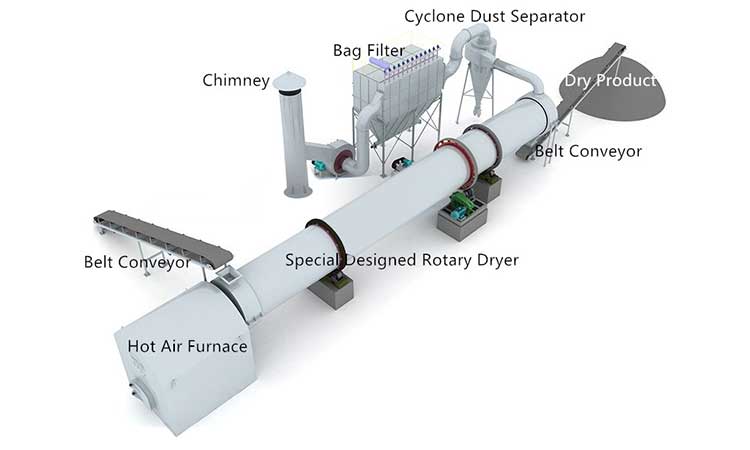

Rotary dryer is mainly used for drying various mineral materials, and it is a special equipment for drying and dehydrating high-humidity materials. The heat source of the dryer comes from the combustion device, which can be used in the way of down-flow or counter flow heating.

Applied material:The rotary drum dryer is mainly used to dry special powder and granule material, such as lightweight calcium carbonate, floridian, magnetic particle, graphite, limestone, sand, coal, slag, clay, wood chips, mining powder etc.

Processing ability:1-50 t/h

Products on this list are top trending product model

We are committed to improve technology, design, process and professional service.

Rotary dryers consist of a horizontally inclined rotating cylinder. Material is fed at one end and discharged at the other end. In direct-type rotary dryers, hot gases move through the cylinder in direct contact with the material, either with or against the direction of its flow. The cylinder is equipped with flights, which lift the material and shower it down through the hot gas stream.

| Model | Rotate speed(r/min) |

Input Temp(℃) |

Power (kw) |

Capacity (t/h) |

|---|---|---|---|---|

| Ф600×6000 | 3-8 | ≤700 | 3 | 0.5-1.5 |

| Ф800×8000 | 3-8 | ≤700 | 4 | 0.8-2.0 |

| Ф800×10000 | 3-8 | ≤700 | 4 | 0.8-2.5 |

| Ф1000×10000 | 3-8 | ≤700 | 7.5 | 1.0-3.5 |

| Ф1200×10000 | 3-8 | ≤700 | 11 | 1.8-5 |

| Ф1200×12000 | 3-8 | ≤700 | 11 | 2-6 |

| Ф1500×12000 | 2-6 | ≤800 | 15 | 3.5-9 |

| Ф1800×12000 | 2-6 | ≤800 | 18 | 5-12 |

| Ф2200×12000 | 1.5-6 | ≤800 | 18.5 | 6-15 |

| Ф2200×18000 | 1.5-6 | ≤800 | 30 | 10-18 |

| Ф2200×20000 | 1.5-6 | ≤800 | 30 | 12-20 |

| Ф2400×20000 | 1.5-5 | ≤800 | 37 | 18-30 |

| Ф3000×20000 | 1.5-5 | ≤800 | 55 | 25-35 |

| Ф3000×25000 | 1.5-5 | ≤800 | 75 | 32-40 |

*Capacity is related to material hardness and size.

If you would like to get more product details and quotations, please contact us !