How to solve problems in stone crusher plant

How to solve problems in stone crusher plant

2020-03-26 15:40:14

2020-03-26 15:40:14

In recent years,gravel aggregate has become a very important and essential raw material in construction projects such as bridges, water conservancy, and roads. Many sand and gravel production lines have encountered some problems in the process of production and operation and cannot achieve the expected results.

1.Selection of basic equipment

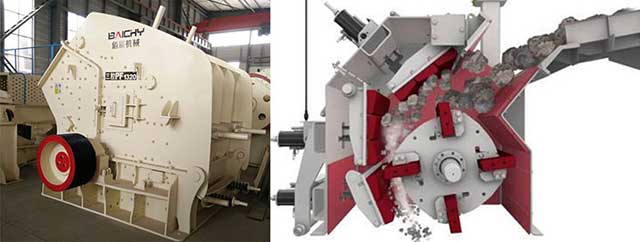

The success of sandstone aggregate production line mainly depends on reasonable equipment selection, which is generally determined by material hardness, soil content and corrosivity index. Taking basalt, granite, diabase, and other materials with high corrosive index and hardness as examples, in order to pursue better product size, the production line mostly uses hammer or impact crushers, but such crushers have large losses.

2.Material chute abrasion

Sand and stone aggregate products have the characteristics of multi-angles, some materials have certain abrasiveness, and the large drop in the process of material transportation, etc., makes the material chute service life shortened, and the degree of wear and impact is serious.So,for the chute with low impact force, the material steel plate shoud be as thicker as possible. This design needs to be avoided for materials that are easily clogged.

3.Environmental issues

To solve this problem, you can calculate according to the position and number of dust collection points first, and place a dust collectors with sufficient air volume in front of and behind the crusher discharge point to reduce dust.If the dust is near the bulk of the finished product garage, in addition to the dust collector, a centrifugal fan can be placed between the top of the warehouse and the bulk machine, and water spray is placed at the material outlet of the bulk machine to reduce dust.

Feldspar Ball Mill Plant Packed to India

Products

Client Case

Services

About Us

News

Contact Us

If you are looking for related products or have any other questions do not hesitate to call our sales line

Tel:+86-371-86555711

Tel:+86-371-86555711

Email:hnbc@baichy.com

Email:hnbc@baichy.com

Whatsapp: +86-15093113821

Whatsapp: +86-15093113821