Whatsapp:+86-15093113821

Whatsapp:+86-15093113821

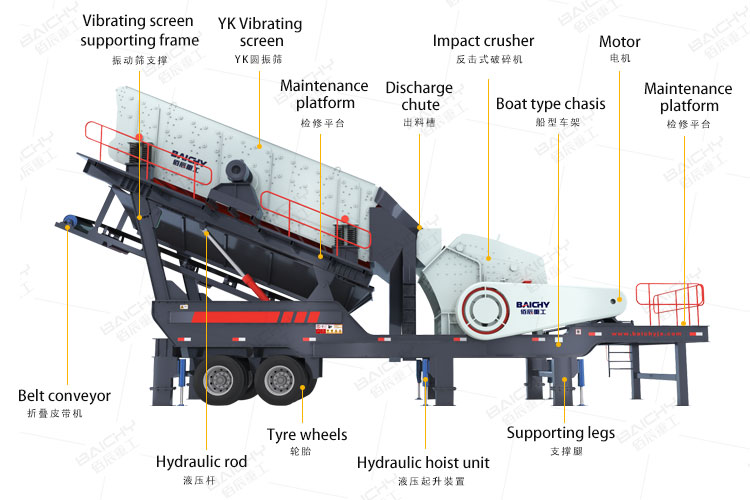

Mobile impact crusher, equipped with high performance impact crusher and screening equipment, or add a feeder as a primary crushing machine. The mobile impact crusher plant has the characteristics of high crushing efficiency, multi-functionality, excellent quality of crushing products and so on. It can meet the crushing and screening requirements of coarse, medium and fine materials.

Applied material: Limestone, granite, basalt, andesite, granite, quartz, pebble, copper ore, iron ore, gold ore, concrete etc.

Processing ability:10-300 t/h

Products on this list are top trending product model

We are committed to improve technology, design, process and professional service.

In the mining and quarry industry, mobile impact crusher plant is usually as secondary crushing machine to process rocks or ores from priamry jaw crusher plant. After impact crusher machine crushing, precisely shaped cubical end products is feed to vibrating screen to get different size material, 0-5mm, 5-10mm, 10-20mm, 20-40mm or some other required size. Vibrating screen is designed to be same level with impact crusher. The oversized material from first layer could be fed to impact crusher directly to crush again. Other required size is sent to stock ground by belt conveyor.

| SMC Impact crusher |

SMC1010PFS | SMC1210PFS | SMC1214PFS | |

|---|---|---|---|---|

| Transport size | ||||

| Length(mm) | 10800 | 12200 | 12500 | |

| Width(mm) | 2480 | 2743 | 2900 | |

| Height(mm) | 4170 | 4200 | 4200 | |

| Alex weight(kg) |

15900 | 17200 | 22100 | |

| King pin weight(kg) |

11300 | 14300 | 17500 | |

| Impact crusher | ||||

| Model | PF1010 | PF1210 | PF1214 | |

| Feed opening(mm) |

400×1080 | 400×1080 | 400×1080 | |

| Vibrating screen | ||||

| Model | 4YK1235 | 4YK1545 | 4YK1548 | |

*Capacity is related to material hardness and size.

If you would like to get more product details and quotations, please contact us !